Experienced Bridge and Culvert Engineer in Washington

Paul Tappel has designed approximately 90 large culverts (ranging from 6′ to 30′ in span) and 95 small bridges (between 20′ and 70′ in span) throughout the state. His extensive experience ensures that each project meets expectations for public safety, vehicle passage, emergency vehicle access (EVA), flood flow conveyance, and fish passage.

Tappel understands that the most common requirement for bridge and culvert designs is facilitating access to private land and residences across streams and rivers. He provides cost-effective, durable solutions that conform to county codes and state regulatory requirements.

Typically, county codes dictate a minimum deck width of 16’ for driveway bridges leading to one residence. Additionally, they require a vehicle live load rating of HS-25 or HL-93, ensuring safety for all legal load vehicles, such as ready-mix concrete trucks. Tappel’s designs also incorporate necessary signage to verify the load rating of driveway bridges.

State regulations necessitate that driveway bridges and culverts accommodate adequate spans and dimensions for flood flow conveyance, with provisions for public safety such as guardrails and considerations for fish passage that protect native fish species, along with the preservation of adjacent stream-side vegetation.

With decades of specialization in culvert and bridge design, Tappel has streamlined the design process into an efficient routine that addresses a variety of situations.

Weathering Steel or Pre-Stressed Concrete Bridges

These superstructures are supported on pre-cast concrete footings, featuring large armor rock placed lower than the channel bottom to prevent scour. Key design features include 100-year flood flow routing considerations, freeboard under bridge beams, Fire Marshal EVA requirements, WDFW stream simulation, and HL-93 live load specifications.

Culverts of Various Materials

Tappel has designed aluminum or galvanized steel arch culverts (180° half-circle configurations) and box culverts supported by pre-cast concrete strip footings. He ensures that thicker corrugated metal gauges are used than required for the expected fill depth. His experience extends to various culvert shapes, including round, pipe arch, box, and horizontal ellipse, alongside pre-cast concrete box culverts.

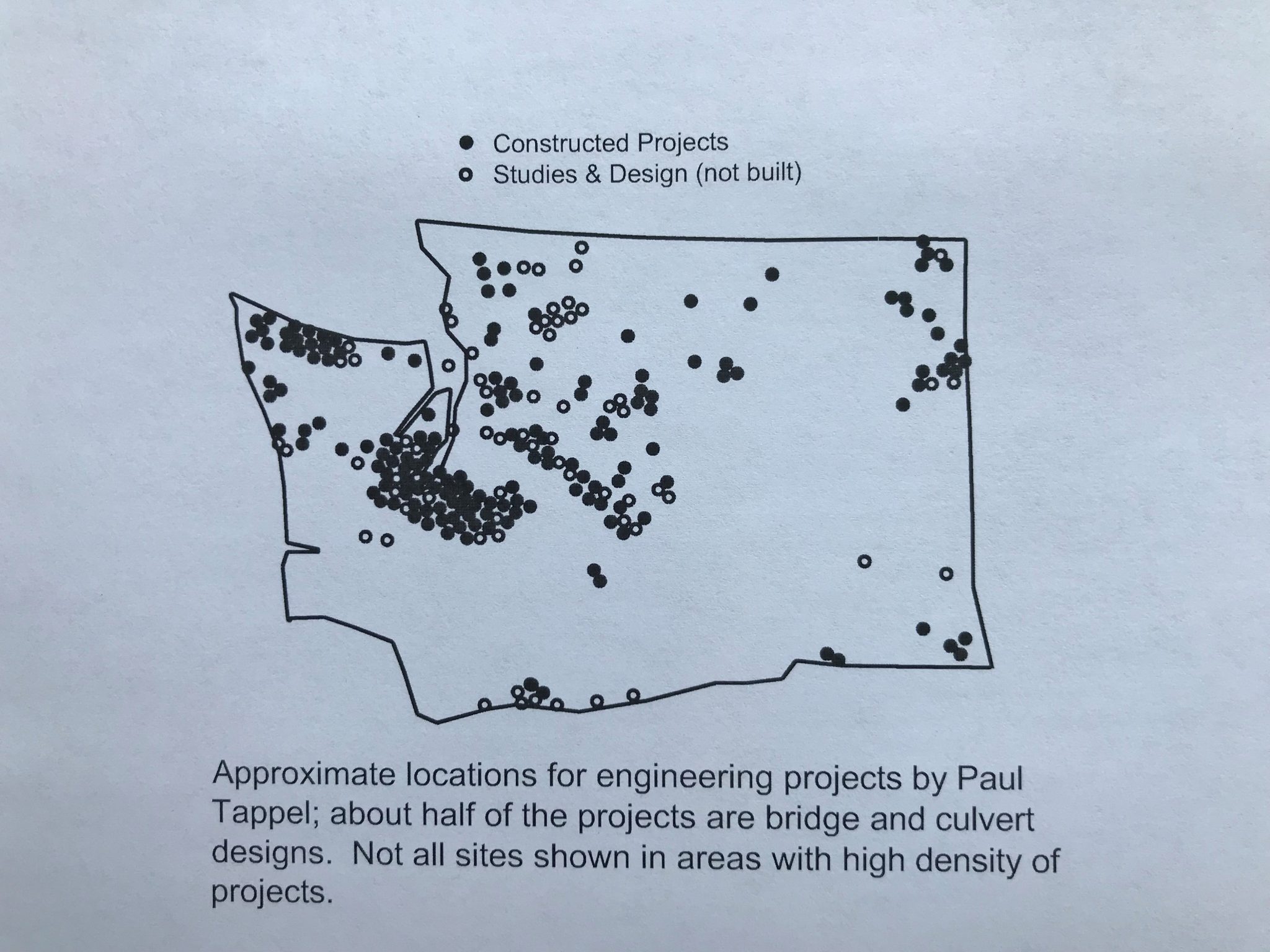

Tappel's Work in Washington

This website features images and descriptions of typical bridges and culverts designed by Tappel, showing their successful construction across Washington.